Integrated approach for flexible production automation

Reduce your costs, cut down on HR requirements, improve product quality, minimise downtime … those are just a few of the ways you can benefit from integrated automation. Atree goes the extra mile when it comes to process optimisation – we view your business as an integrated system. Our software developers always look at the big picture for every company. It works.

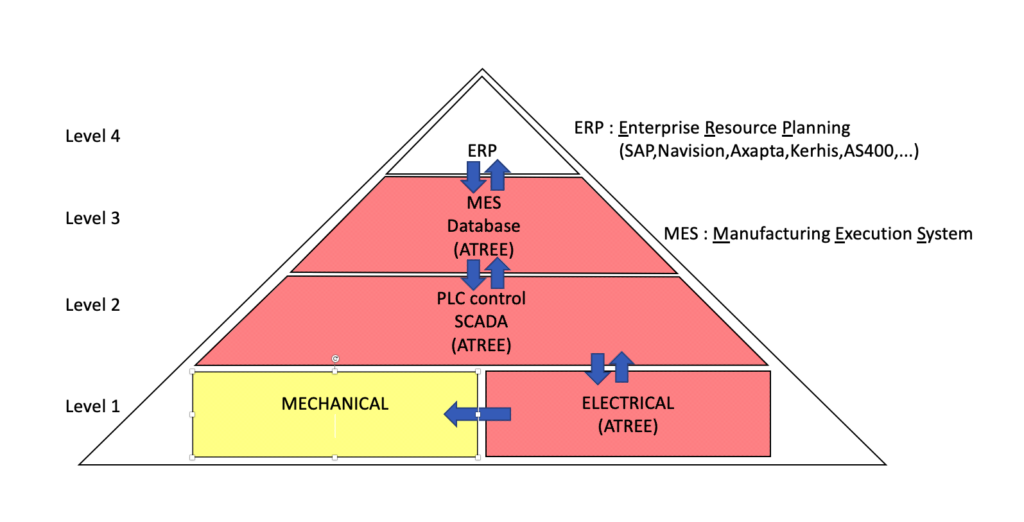

Wherever you see process optimisation, you will also see three-letter acronyms: MES, ERP, OEE, etc. To really achieve full automation, you need to have all these things integrated under one system. And that is exactly what Atree can do for you: we integrate our PLC and SCADA programming with your company’s existing software packages. Benefit from flexible production automation in its purest form.

Strengths of Atree

- Integrating PLC and SCADA with existing systems

- Specialist programmers for integrated automation

- Seamless exchange of valuable data

- One integrated platform

MES A balanced pyramid

The core of integrated process optimisation is seamless interactions between different systems supplying valuable data. Planning and production are managed through your ERP. The machines and their interfaces then respond by sending feedback that automatically launches the correct downstream processes – no human intervention needed, and no misunderstandings.

Specialists at work

Integrated automation is a field of its own. At Atree, we have three programmers specialising in this niche. While their colleagues are busy finalising every detail of the PLC and SCADA systems, these specialists are hard at work building this extra layer for your process optimisation – linking all your processes on one platform, right through to your MES and ERP.